SILC: THE CHOICE OF ITALIAN FASHION

The

SILC industrial garment presses are the result of experience gained over

more than 20 years in the field of steam finishing in more than 40 countries

all over the world.

These

presses have been expressly designed with the precious collaboration of

the best technicians in the finishing sector of some of the most well

known garment manufacturers and offer all the working solutions which

are absolutely necessary nowadays to obtain high quality finishing of

any fabrics.

Among

the main characteristics are:

Functioning. Closing

and controlled descent of top buck without subsequent blocking in the

closed position. Complete closig of bucks, only if required, by the manual

intervention of the operator.

Controls and bucks. Buck

movement control and vacuum control by means of pedal. Blocking and steaming

on top buck by means of levers positioned on the buck itself; steam heated

and steaming top buck. Steam heated and vacuum lower buck; models S/IP4-S/IP1-S/IP6

and S/IP9 also have steaming lower buck.

Pressing

"on distance" - Rapid finishing - Pressure. All the presses are equipped with double pressure regulation. (Visible on pressure gauge). The first gives the possibility

of limiting the distance between the bucks without completely closing

(regulation between 30 mm. and 0 mm.) and of rapid finishing, closing

the bucks but not blocking them in the closed position (between I and

4 ate max.) The second gives the possibility of varying and establishing

constant finishing pressure with blocking of bucks in closed position

(between 0 and 12 ate max.).

Safety devices. Safety

guards are applied on all the bucks, which enable the operator to position

the garment without risk.

Accessories. The presses are designed to be equipped with accessories for self contained

functioning, such as boiler for steam production and vacuum and for the

completion of finishing, such as steam iron set, air-steam gun, spotting

group, fabric safe, and blow on lower buck Elimination of steam and heat

issued from top buck, by means of central vacuum.

Automation. If

automation of the various phases is required, this is possible either

by timers or electronic control box.

|

|

INDUSTRIAL PNEUMATIC GARMENT PRESSES (FINAL PRESSING) |

|

|

Industrial press

for final pressing, pneumatic with safety guard, to be connected to

central steam, vacuum and compressed air. Dual control, "on distance"

pressing. (Not including steam trap) |

|

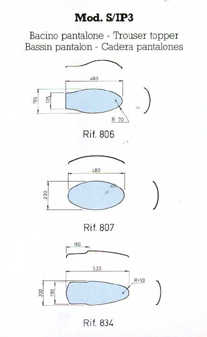

MOD. S/IP3 COD. 11173110 |

Topper |

|

|

|

|

|

ACCESSORIES ON REQUEST |

|

15012300 |

Electric boiler

(9 Kw. or 12 Kw.) with pump |

|

15022300 |

Vacuum group with

0,5 HP motor |

|

15032300 |

Twin cylinder

compressor group with 2 HP motor |

|

15042300 |

Steam iron group |

|

15122300 |

Automation by

2 timers (steaming and vacuum) |

|

15132300 |

Automation by

3 timers (steaming, vacuum and opening) |

|

15152300 |

Garment safe on

top buck for S/IP4 |

|

15152410 |

Garment safe on

top buck for S/IP1 |

|

15152440 |

Garment safe on

top buck for S/IP3 |

|

15183073 |

Blow on lower

buck for all above models |

|

15193074 |

Steam lower buck

for S/IP3 |

|

15162300 |

Special voltage

on accessories (240/415 or 60 HZ) |

|

Technical

Details |

S/IP3 |

|

steam:

4-6 bar |

12

kg/h |

|

Compressed

air: 6 bar |

80

lt/min. |

|

Air

intake: 250 mm H²O |

80

mc/h |

|

Dimensions: |

130x115x145

(h) |

|

Weight |

kg.

220 |